News

Latest company updates and industry news

Accelerate Your Improvements – Learn How To Bring “Agile“ into DMAIC

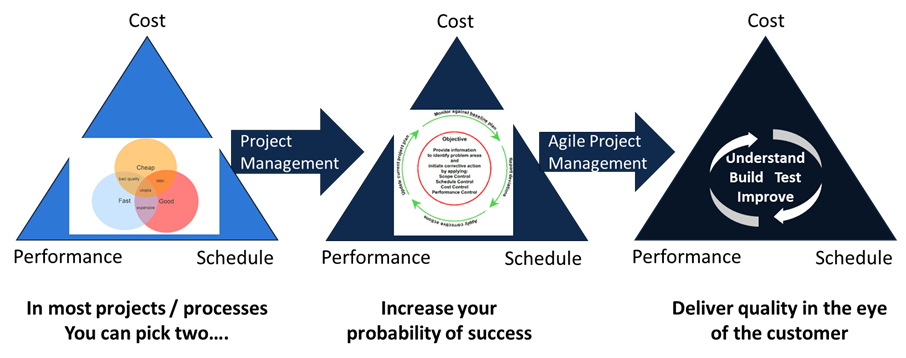

We have all heard of Agile as the “next great thing”.… so what exactly is Agile and how does it complement the more traditional approach to OpEx activities?

There are three things Agile will bring to your improvement ‘tool box’

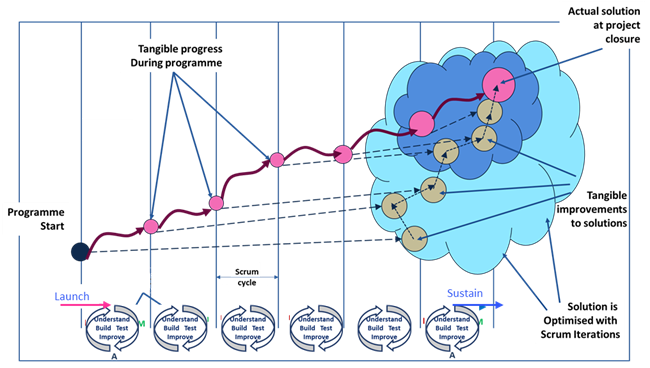

- The ability to work on complex problems allowing you to evolve OpEx from the traditional ‘one Y, one project’ approach – And still keep your sanity whilst you are doing so!

- An iterative understand-build-test-improve approach to planning, guiding, and accelerating improvement projects.

- An elevated level of customer / stakeholder involvement, ensuring that solutions are recognised to deliver quality in the eye of the customer. Insights gained from the critique of an iteration are used to determine what the next step should be in the project.

Together this results in more tangible progress during the programme, giving a real sense of value and speed! This is particularly important when you are trying to tackle complex issues with broad multi-functional scope.

Orietta is our Agile Scrum Master, and she can help you develop Agile enabled projects that build on your existing capabilities (rather than attempt to teach you a stand-alone new toolbox). Orietta will help you leverage Agile to the full, and make sure you feel the benefit!

Look out for our Webinar on AgileDMAIC© on 1st May and register below if you are interested in joining the discussion.

Don't Forget The Soft Stuff!

Traditional Lean Six Sigma training equips delegates with a fantastic “toolbox”, but real success comes when the hard “tools” training is combined with additional “soft skills” development to help with the practical implications of driving improvement projects in busy organisations.

Michaela & Orietta have been working with several clients recently to supplement their Green Belt Training with additional 1 day modules on Leading Change, Effective Facilitation, and Project Management. Often taken for granted, developing these skills can make a really significant difference.

Tangible benefits our clients are seeing include

- Faster project delivery

- Much better management of project barriers and blockers

- Much greater sponsor and stakeholder engagement resulting in better solutions

- Less frustrated GBs and BB

Delegate feedback suggests they also appreciate the additional soft skills training input:

Find out more about ‘Soft Skills’ Development by contacting Michaela or Orietta

Do What Private Equity Firms Do

Learn how to uncover hidden value with an OpEx Assessment.

Benchmarking your Opex Activities against best practice is a great way to assess strengths, weaknesses, and pinpoint focus areas for improvement. At Process Insight we have developed several self-assessment tools which we often use with our clients to help shape their programmes.

Over the last few years we have also worked with Private Equity company, Pamploma, to use these tools in helping them extract value from the companies in which they invest.

We have found the Process Insight Opex Assessments very useful in the due diligence process when both buying and selling companies.It gives us a great view on the comparative performance of an organisation that does not come through in the financials alone.

Derek Whitworth

Operating Partner, Pamploma Capital Management

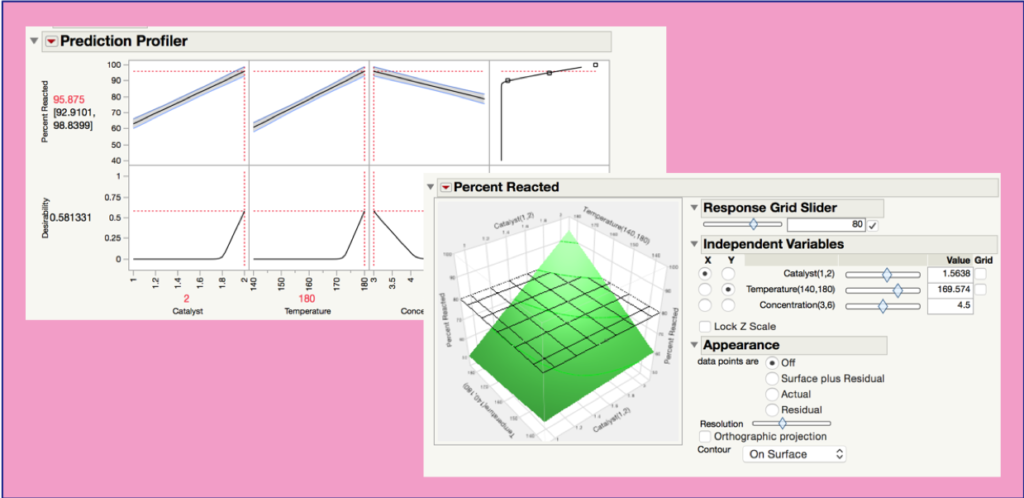

Don't Be Frightened By DOE!

DOE (Design of experiments) is definitely towards the more “specialist” end of the spectrum of the Lean Sigma toolbox. However, capabilities in JMP are making it easier and easier all the time. It’s a great tool for supporting product design, robust process design & scale up – we believe everyone involved in new product/process development and process transfers should have DOE as an essential part of their kitbag.

Recent DOE training with Clients includes Smartkem (flexible electronics), Johnson Matthey (Pharmaceuticals), Aesica (Pharmaceuticals)

Some example feedback from recent Smartkem Training:

‘Perfect level for both those new to stats and to those with more experience” (Katy)

“Brilliant Training” (Jesse)

“Great mix of theory and practice” (John)

Don’t be frightened – get trained!

Congratulations To All Our Recently Accredited 'Belts'

At Process Insight we help organisations solve their business problems in a way that supports the personal development of the people involved. Consequently we are particularly delighted to offer our congratulations to those we have recently coached & certified. Certification represents a very important milestone and is a great demonstration of sustained leadership & business impact. If you would like to find out more about becoming accredited then give us a call on 07785 927144.

At Process Insight we help organisations solve their business problems in a way that supports the personal development of the people involved. Consequently we are particularly delighted to offer our congratulations to those we have recently coached & certified. Certification represents a very important milestone and is a great demonstration of sustained leadership & business impact. If you would like to find out more about becoming accredited then give us a call on 07785 927144.

Master Black Belt certification

Alison Hartley Teledyne e2v

Black Belt certification

Rachelle Heslop Fuji Diosynth

Tom Clayton Teledyne e2V

Green Belt certification

Miroslav Puric Beltrame

Liridon Krasniqiv Beltrame

Hans-Ulrich Kilchhofer Beltrame

Dario Maffucci Beltrame

Louise Gould Business Stream